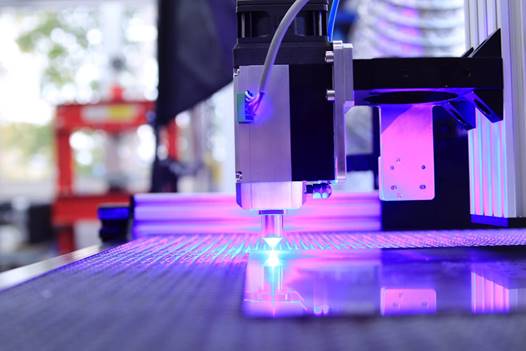

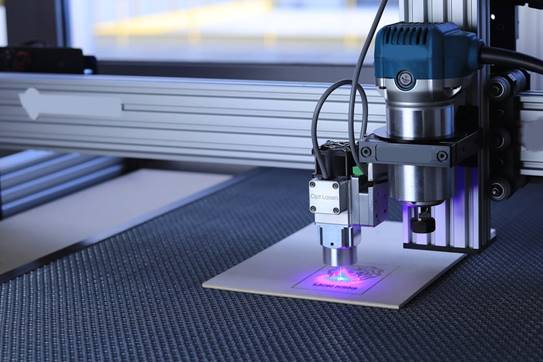

Buying a uv laser marking machine is a significant investment, and selecting the right one requires careful consideration. With a wide range of options available in the market, it’s important to know what features and specifications matter most to ensure you get a machine that meets your needs. Factors such as marking precision, material compatibility, durability, and ease of operation can greatly impact both performance and long-term value. In this post, we’ll explore the top things to check before buying a UV laser marking machine to help you make an informed decision.

9 Things To Check Before Buying A UV Laser Marking Machine

Marking precision and accuracy

A key factor to consider when purchasing a UV laser marking machine is its marking precision and accuracy, as these directly impact the quality and consistency of the results. High precision ensures clean, detailed, and sharp markings, which is especially important for intricate designs, logos, or serial numbers.

Machines with low accuracy may produce inconsistent marks, misaligned designs, or uneven depths, affecting the overall appearance and reliability of the work. Evaluating precision and accuracy before purchase helps buyers select a machine capable of delivering professional-quality results consistently, ensuring that the investment meets both current and future project requirements.

Supported materials

A key factor to consider before purchasing a UV laser marking machine is the range of supported materials, as it directly impacts the machine’s versatility and suitability for your projects. Different machines are optimized for marking on specific substrates such as plastics, metals, glass, or coated surfaces.

Ensuring the machine can handle the planned materials prevents limitations and avoids additional expenses on specialized equipment. By checking material compatibility beforehand, buyers can choose a UV laser marking machine that meets their current needs while providing flexibility for a variety of applications in the future.

Laser power and wavelength

A key factor to consider before purchasing a UV laser marking machine is its laser power and wavelength, as these determine the machine’s efficiency and suitability for various applications. Laser power affects the speed and depth of marking, while the wavelength impacts how effectively the laser interacts with various materials.

Choosing the right combination ensures clean, precise markings without damaging the surface. Evaluating laser power and wavelength before purchase helps buyers select a machine that can handle their intended projects efficiently, delivering consistent, high-quality results across a range of materials.

Marking speed

A key factor to consider when purchasing a UV laser marking machine is its marking speed, as it directly impacts productivity and workflow efficiency. Faster marking speeds allow for higher output, making the machine suitable for large-scale or time-sensitive projects, while slower machines may limit throughput.

It’s important to consider the balance between speed and accuracy, as extremely fast machines should still maintain precise, consistent markings. By evaluating marking speed before purchase, buyers can choose a UV laser marking machine that meets both their production demands and quality expectations, ensuring a smooth and efficient operation.

Build quality and durability

A key consideration when purchasing a UV laser marking machine is its build quality and durability, as these factors significantly impact the machine’s long-term performance and reliability. Machines constructed with high-quality materials and robust components are better able to withstand continuous use, vibrations, and operational stress.

Durable construction also minimizes the need for frequent repairs or part replacements, reducing downtime and maintenance costs. By assessing build quality and durability before purchase, buyers can ensure they invest in a UV laser marking machine that delivers consistent results, maintains stability over time, and provides a dependable solution for both current and future projects.

Software compatibility and ease of use

A key factor to consider when purchasing a UV laser marking machine is software compatibility and ease of use, as these directly impact how efficiently you can operate the machine. Intuitive, user-friendly software allows for easy import of designs, adjustment of marking parameters, and smooth integration with existing workflows.

Compatibility with common file formats and design programs ensures that you can work with your preferred tools without issues. Evaluating software usability before purchase helps buyers select a UV laser marking machine that simplifies operation, reduces the learning curve, and enables consistent, high-quality results with minimal effort.

Safety features

A key consideration when purchasing a UV laser marking machine is its safety features, which are crucial for safeguarding both the operator and the equipment during operation. Key safety measures may include protective enclosures, emergency stop buttons, interlock systems, and warning indicators that prevent accidents and reduce the risk of damage.

Ensuring that the machine comes with robust safety mechanisms allows users to operate it confidently and minimizes potential hazards in the workspace. By prioritizing safety features before purchase, buyers can select a UV laser marking machine that provides a secure, reliable, and worry-free working environment.

Cooling system efficiency

A key factor to consider when purchasing a UV laser marking machine is the efficiency of its cooling system, as it directly impacts performance and longevity. An effective cooling system prevents overheating during extended operation, maintaining stable laser output and consistent marking quality. Machines with inadequate cooling may experience reduced efficiency, frequent shutdowns, or even damage to internal components over time.

By evaluating cooling system performance before purchase, buyers can ensure that their UV laser marking machine operates reliably under continuous use, delivers consistent results, and requires less maintenance, making it a more durable and dependable investment.

After-sales service and support

A key factor to consider when purchasing a UV laser marking machine is the quality of after-sales service and support, as it plays a crucial role in ensuring smooth operation and long-term reliability.

Reliable support includes timely technical assistance, guidance for troubleshooting, and access to replacement parts when needed. Strong after-sales service reduces downtime, helps resolve issues quickly, and provides confidence that the manufacturer stands behind their product.

Bottom Line

Choosing the right UV laser marking machine requires careful evaluation of several critical factors to ensure a smart investment and consistent results. From marking precision and material compatibility to laser power, marking speed, build quality, software ease of use, safety features, cooling efficiency, and after-sales support, each element plays a key role in the machine’s performance and reliability. By thoroughly checking these aspects before purchase, buyers can avoid common pitfalls, select a machine that aligns with their project requirements, and enjoy smooth, efficient operation.